Categories

Recent Posts

1. Printed circuit board

It is the core part of PCBA. Its design must follow the principles of electronic circuits. Electronic components, power supplies, signal lines and other connection lines are designed by professional software and printed on physical circuit boards.

2. Components

It is a part of PCBA, including resistors, capacitors, inductors, diodes, transistors, integrated circuits, and so on. These components are placed on the PCB according to the circuit design requirements.

3. Assembly

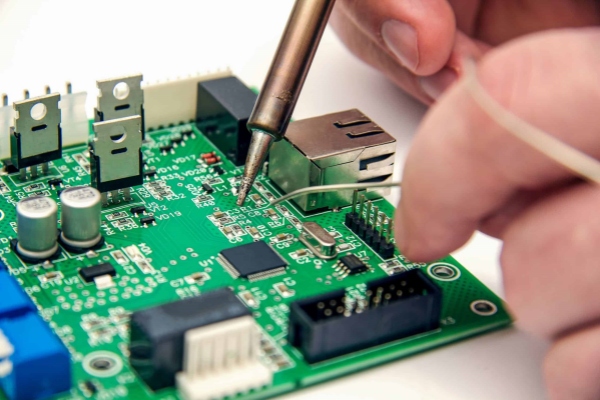

It is a key process of PCBA, including mating, welding, testing and other steps to ensure that the components are properly connected to the PCB and achieve the function of the circuit design.

4. How to make PCBA?

PCBA production is a complex and delicate process that requires professional knowledge and equipment.The following are the general steps for PCBA production:

(1)Circuit design:Design circuit diagrams according to the functional requirements of electronic products, and use professional EDA software, such as Altium Designer, etc., to design circuit boards.

(2)Printed circuit board manufacturing: Printing the designed circuit diagram onto a physical circuit board, which usually requires multiple steps such as photolithography, etching and drilling.

(3)Component sourcing: According to the circuit design, purchase the corresponding electronic components, including resistors, capacitors, inductors, diodes, transistors, integrated circuits, etc.

(4)Component assembly: Place the purchased components on the printed circuit board according to the circuit design requirements, which usually requires professional equipment such as placement machines.

(5)Welding: Welding components to PCBs, including wave soldering, reflow soldering, etc.

(6)Testing: Testing the soldered PCBA, including visual inspection, electrical testing, functional testing, etc., to ensure that its functions are correct and free of defects.

(7)Packaging: Packaging and labeling of the tested PCBA, including anti-static packaging, moisture-proof packaging, etc., to ensure its safety during transportation and use.

EMAIL US: Sales@ucreatepcb.com

It is widely used in almost all electronic product fields, such as mobile phones, computers, home appliances, automotive electronics, medical equipment, and industrial control. Understanding and mastering PCBA production technology will be of great help to in-depth understanding and innovation of electronic products. Its value is mainly reflected in

(1)High integration: PCBA integrates the circuits and components of electronic devices on one circuit board, which greatly improves the integration and miniaturization level of electronic devices.

(2)Strong functions: PCBA can realize complex electronic circuits and functions, and is a key technology for realizing intelligent electronic devices.

(3)High efficiency: PCBA production and assembly can be highly automated, which greatly improves the production efficiency and quality stability of electronic devices.

Related Posts:

1.The quality control of PCBA processing

2.The difference between PCB and PCBA

3.Quality Control of PCBA Circuit Board Machining

4.Three Ways to Complete PCB Assembly

5.Turnkey PCB Assembly Services

Welcome to consult our sales engineer with BOM list and Gerber file