Categories

Recent Posts

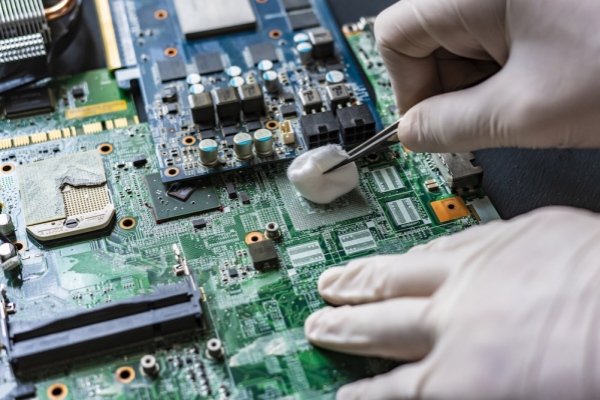

The assembly of PCBA of general electronic products requires the SMT+THT process, which includes wave soldering, reflow soldering, manual soldering and other welding processes. No matter what method of welding is used, the assembly (electrical assembly) process is the main one. Assembly sources of contamination.

Contaminants are defined as any surface deposits, impurities, slag inclusions and adsorbed materials that reduce the chemical, physical or electrical properties of PCBA to unqualified levels. Mainly include the following aspects:

(1) The components that make up the PCBA, the contamination or oxidation of the PCB itself, etc. will cause pollution to the PCBA board surface;

(2) During the manufacturing process of PCBA, solder paste, solder, solder wire, etc. need to be used for welding. The flux will produce residues during the welding process to cause contamination on the PCBA board surface, which is the main pollutant;

(3) Fingerprints will be produced during the manual soldering process. The wave soldering process will produce some wave soldering claw and foot marks and welding tray (jigs) marks. There may also be other types of contaminants in varying degrees on the PCBA surface, such as Hole-blocking glue, residual glue from high-temperature tape, handwriting and flying dust, etc;

(4) Dust in the workplace, vapor, smoke from water and solvents, tiny organic particles, and charged particles caused by static electricity adhere to PCBA.

Why should we clean PCBA?

In the past, people did not know enough about cleaning, mainly because the PCBA assembly density of electronic products was not high, and they believed that flux residue was non-conductive and benign and would not affect electrical performance. Today's electronic assembly designs tend to be miniaturized, with smaller devices and smaller spacing. The pins and pads are getting closer and closer. The existing gaps are getting smaller and smaller, and contaminants may get stuck in the gaps. This means that if relatively small particles remain between the two pads, they may cause a potential short circuit.

According to PCBA electrical assembly quality problem analysis statistics provided by China Saibao Laboratory Reliability Research and Analysis Center, post-use failure problems such as short circuits and open circuits caused by corrosion and electromigration account for 4% and are one of the major killers of product reliability.

Contamination may directly or indirectly cause potential risks to PCBA. For example, organic acids in the residue may cause corrosion to the PCBA; during the power-on process, the electric ions in the residue will cause the movement of electrons due to the potential difference between the two pads. It is possible to form a short circuit and cause the product to fail; the residue will affect the coating effect and cause problems such as failure to apply or poor coating; it may also not be found temporarily. Over time and changes in ambient temperature, coating cracks and warping, causing reliability issues.

It can be seen from the growing electronic product market that modern and future electronic products will become smaller and smaller, and the requirements for high performance and high reliability will be stronger than ever before. Thorough cleaning is a very important and highly technical task. It directly affects the working life and reliability of electronic products, and is also related to the protection of the environment and human health.

Related Posts:

3.Top 10 PCB Circuit Board Manufacturers in China

4.What Does The Cost of PCB Asembly Include?

5.The quality control of PCBA processing

Welcome to consult our sales engineer with BOM list and Gerber file