Categories

Recent Posts

Metal core PCBs (Printed Circuit Boards) have become increasingly popular in recent years due to their superior heat dissipation capabilities, which make them ideal for high-power LED lighting and other thermal management applications. As a professional marketer, I would like to introduce the benefits of metal core PCBs and explain why they are the best choice for many applications.

Firstly, metal core PCBs are designed to transfer heat away from the LED components more effectively than traditional FR4 boards. This is because the metal core acts as a heat sink, which helps to dissipate heat more quickly and effectively, resulting in better performance and longer lifespan of the LED components. This means that metal core PCBs are perfect for high-power applications where heat management is crucial.

Secondly, metal core PCBs are more durable than traditional PCBs, as they are less prone to thermal expansion and contraction. This is due to the fact that the metal core has a higher coefficient of thermal conductivity than FR4, which means it is less likely to expand and contract under temperature changes. This makes metal core PCBs ideal for applications where the board will be subjected to high temperature variations or thermal cycling.

Finally, metal core PCBs are versatile and can be used in a wide range of applications, including automotive, aerospace, medical, and consumer electronics. They are particularly well-suited to applications that require high performance and reliability, such as LED lighting, power supplies, and motor control systems.

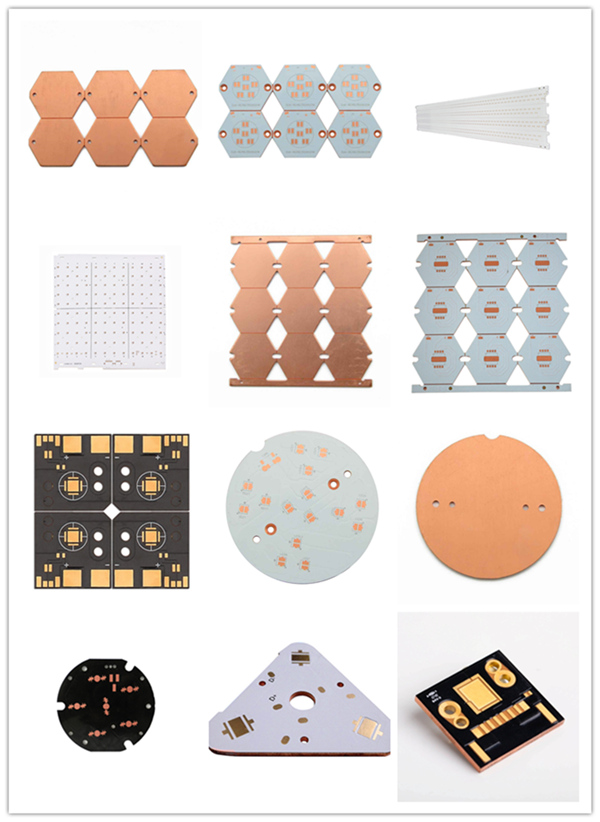

Metal Core PCBs can be classified into different types based on their construction and design. Here are some common types of Metal Core PCBs:

Single Layer Metal Core PCB: This type of Metal Core PCB has only one layer of circuitry on the metal core, which is usually made of aluminum.

Double Layer Metal Core PCB: This type of Metal Core PCB has two layers of circuitry on the metal core, which are separated by a layer of insulating material.

Multilayer Metal Core PCB: This type of Metal Core PCB has three or more layers of circuitry on the metal core, which are separated by multiple layers of insulating material.

Hybrid Metal Core PCB: This type of Metal Core PCB combines metal core with other materials, such as FR4 or ceramic, to achieve specific properties, such as improved heat dissipation or reduced weight.

Flexible Metal Core PCB: This type of Metal Core PCB has a flexible metal core, typically made of copper, that allows the board to bend or flex. This type of PCB is commonly used in applications where space is limited, and flexibility is required.

In conclusion, metal core PCBs offer a range of benefits that make them the ideal choice for high-power LED lighting and other thermal management applications. They are more durable, reliable, and versatile than traditional PCBs, and can be used in a wide range of applications. If you are looking for a high-performance PCB solution, then metal core PCBs are the way to go.