Categories

Recent Posts

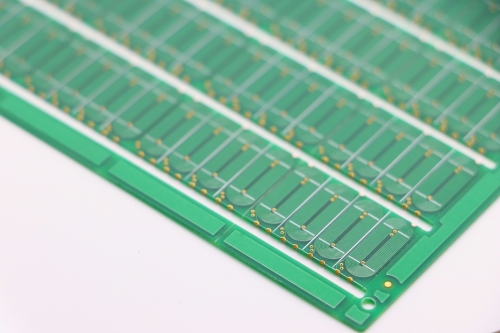

As a commonly used electronic manufacturing material, the thermal expansion coefficient of fr4 substrate is an important performance indicator. In this article, the thermal expansion coefficient of FR4 substrate will be discussed in detail to reveal the principle and application behind it.

The coefficient of thermal expansion has important applications in electronics manufacturing. It guides the assembly and soldering process of electronic components. In the environment of large temperature changes, the selection of materials with similar coefficients of thermal expansion can reduce the stress of the soldered joints and improve the reliability of the soldering. The study of thermal expansion coefficients is also a key factor in the design and performance optimisation of printed circuit boards. By adjusting the material ratio and selecting the appropriate layer thickness ratio, the risk of board distortion and breakage due to temperature changes can be reduced.

The thermal expansion coefficient of FR4 substrates is an important parameter that affects their performance and application range. By thoroughly studying and understanding the thermal expansion coefficient of FR4 substrates, we can better select and use the material to improve the reliability and stability of electronic products.In the future, with the continuous development and innovation of the electronics industry, the study of the thermal expansion coefficient will become more important and more feasible solutions will be derived.

Related Posts:

2. What is the general frequency of FR4 material applied to FR PCB?

3. Top 10 PCB Circuit Board Manufacturers in China

Welcome to consult our sales engineer with BOM list and Gerber file