Categories

Recent Posts

On March 27, President Joe Biden signed a presidential resolution granting the use of the Defense Production Act (DPA) to allow the Defense Department to use $50 million (340 million yuan) to support the PCB (printed circuit board) and advanced chip packaging industry. The move is designed to ensure that the PCB can be produced in the United States.

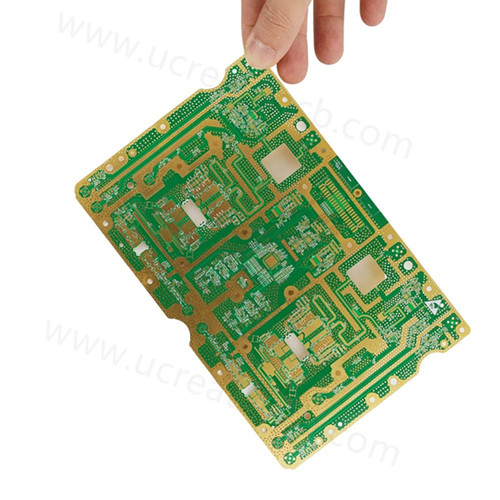

Unimpressive PCB

A PCB is short for a printed circuit board, or simply a circuit board with wires and pads that connect the points together. PCB is not significant in the entire semiconductor industry chain, but it is widely used. All electronic devices, whether personal computers, communication base stations or mobile phones, household appliances or mission-critical servers or military equipment, will use printed circuit boards.

(China PCB industry market size and downstream application market size forecast analysis in 2022-Commerce Intelligence Network)

Why is the United States starting to value the PCB?

All this starts with the decline of American manufacturing. Labor costs in the US have long been significantly higher than those in other countries, but its productivity levels make up for the difference. However, with the process of globalization, many low-level and low-technology industries began to shift to Asia, which brought about the loss of low-technology industries.

As it happens, the PCB industry is a labor-intensive industry. A large number of automation equipment requires manual operation and assembly line operation. A medium-sized PCB enterprise has thousands of employees.

Therefore, the history of PCB has also experienced a change from "European-led" to "Asia-led".

In 2000, more than 70% of the global PCB output value was distributed in the Americas, Europe and Japan. In 2008 and 2016, the share of global PCB output in the Americas, Europe and Japan declined, while the global share of Chinese mainland PCB output increased continuously, from 31.18% in 2008 to 47.36%. Due to the relatively low labor costs, PCB has begun to take root in Asia with an unstoppable trend, and the focus of the global PCB industry has gradually shifted to Asia. Now, Asia has undoubtedly become a gathering place for PCB development, forming a new pattern with Asia (especially Chinese mainland) as the center and other regions as the auxiliary.

Statistically speaking, Information's 2022 study shows that compared with the US, which has only five PCB manufacturers, China has the most PCB manufacturers, with 69 companies working in the industry. by Taiwan, China (27), Japan (23), and South Korea (14). The survival of the PCB industry in the United States is already at stake.

But what is interesting is that when the United States issued the Chip Act with great bang, and wanted to pull chip manufacturing back to China, most of them did not pay attention to or even ignore the PCB link. At the same time, there was also the chip packaging link.

SIA has published two consecutive reports for the US government, namely "Government Incentive Plan and Competitiveness of Semiconductor Manufacturing in the United States" and "Overview of Semiconductor Development in the United States 2020". If "packaging" and "PCB" are used as keywords, without considering the annotation content, then the results will be zero. In addition, according to the own statistics of the United States, the global trial production share of packaging and testing (OSAT) in the United States is significantly behind.

In fact, the importance of chip packaging link needless to say, many industry insiders have pointed out that with the development of Moore's Law to reach the limit, chip packaging will become the next technology to squeeze dry Moore's Law. More and more exploration of packaging, and the proposed Chiplet also shows the importance of packaging for cost. The PCB industry, especially the packaging substrate of the subdivision track, can be said to be the center of the American semiconductor manufacturing self-sufficiency plan.

And the PCB industry seems to be a constant reminder of American manufacturing. In recent years, the price of PCB materials is constantly rising. The basic material made by PCB is CCL (copper coated foil laminate), whose upstream is mainly copper foil, glass fiber cloth, epoxy resin and other raw materials. Prices of a variety of upstream raw materials for copper-clad panels have continued to rise since last year. Take the low-end price of 35um copper foil, for example, copper foil prices have rebounded 11.9% from the low point at the end of October last year (including processing fees rebounded

Out of the importance of manufacturing backflow, the United States began to pay attention to the PCB industry seems justified.

Does China need to worry about PCB development?

So does China all need to worry about the development of PCB? As mentioned above, the strength of PCB in China is not weak, but China's PCB industry is "big but not strong".

Since 1956, China began to PCB development work. In the 1960s, mass production of single-sided circuit board, small batch production of double-sided circuit board and began to develop multi-layer PCB board. In the 1970s, due to the limitation of historical conditions at that time, the development of printed board technology was slow, making the whole production technology lag behind the advanced level of foreign countries.

In the 1980s, the advanced single-sided PCB board, double-sided circuit board and multi-layer printed board production line were introduced from abroad, which improved the production technology level of printed board in China. In the 1990s, printed board manufacturers from Hong Kong, Taiwan and Japan came to the mainland to set up joint ventures and wholly owned factories, which made the production and technology of printed board advance by leaps and bounds.

Local circuit board enterprises have sprung up in the whole country, taking the express train of reform and opening up. In 2006, China has replaced Japan to become the world's largest PCB production base and the most active country in technology development.

In just ten years, China has been in the PCB market, one of the important reasons is that the high degree of marketization of Chinese PCB enterprises is high.

In addition to similar Huawei this brand manufacturers, ODM in terms of circuit and wiring decided to outsourcing company (mainly Taiwan, China area PCB foundry), the foundry feedback the China upstream PCB manufacturers production capacity, the formation of manufacturing cluster also helps to speed up the product time to market, so as to improve its production efficiency and delivery capacity.

Around 2018, it can be regarded as the outbreak period of domestic PCB industry development. With the improvement of the global PCB market, domestic PCB factories also have a great capital advantage, many leading manufacturers such as Shennan, Shenghong, Jingwang and so on in expanding production capacity. For example, Shennan Circuit, which was listed in 2017, raised RMB 1.268 billion, and plans to build Nantong Shennan General High-density multi-layer PCB (Phase I) project.

At the same time, in 2018, the domestic PCB industry merger and reorganization market set a double record high of both the number of transactions and the transaction amount, and a number of merger and reorganization cases occurred. For example, Zhongjing Electronics acquired 55% equity of Zhuhai Yisheng and 29.18% equity of Yuansheng Electronics with RMB 330 million yuan. After the acquisition, Zhongjing Electronics holds 76.12% equity of Yuansheng Electronics; Bomin Electronics intends to acquire 100% equity of Juntian Hengxun for RMB 1.25 billion yuan.

The development of PCB in China is very fast. Is China's PCB industry big enough? This raises a further question. How big is it, after all?

In 2019, when China's manufacturing sector accounted for 20 percent of the world's total manufacturing sector, Miao Wei, then minister of industry and information technology, said China had become the world's manufacturing power. According to the data, the output value of China's PCB industry accounts for about 53.7% of the world, more than half of the global output value. From a point of view, China's PCB industry is large enough.

However, according to the statistics of different PCB output value in major regions of Prismark, 47.8% of PCB output value in China comes from the middle and low layer plate. In the high multilayer, HDI board, IC packaging substrate, rigid binding board, metal substrate and other high-end products accounted for a very low proportion of only 48.1%, while the United States, Japan, Asia in the high-end products accounted for 68.6%, 80.4%, 84.7%. Therefore, although China's PCB output value is the first in the world, but there are still shortcomings in high-end products.

So, China's PCB is finally applied in which part of the terminal demand?

The domestic PCB market is mainly driven by 4G and 5G base stations, especially the demand of PCB and PCB in server / data storage accounts for more than 40%. The antenna array of 5G base station needs to be arranged on the PCB, and the PCB is used as the carrier and line connection. The scale effect also diluted the cost of PCB.

There is a market, enterprises and demand. At present, China's PCB industry will still flourish.

Small and medium-sized PCB enterprises are still in crisis

In the development of the market, there are also many PCB enterprises fell with the flood.

2022 may be a turning point for the development of many small and medium-sized PCs. " This may be the worst year for the PCB industry in 20 years."Enterprises have been deep in the PCB industry for many years revealed that in the first half of the PCB industry many factories are in the state of stop line."2008 may not be as bad as this year.”

In May last year, a PCB factory in Foshan invited suppliers and creditors to deal with the payment and debt due to the capital turnover difficulties and the high debt. In October, —— Founder Technology, an old PCB listed company, announced that it received the Notice from Beijing First Intermediate People's Court in June this year due to debt over 1 billion yuan.

In March this year, an old PCB enterprise went bankrupt and restructured, Sichuan Shenbei Circuit Technology Co., Ltd. issued the "letter to all creditors" said: the circuit board production and processing industry is facing the shortage of domestic demand, foreign trade orders plunged, the enterprise operation is facing serious difficulties. But our cash flow is almost dried up, to the time of life and death.

The reason for this may be that 5G PCB has put forward new requirements for space, and also has new requirements for the characteristics of materials. The main raw materials of PCB are copper clad plate, semi-cured sheet, copper foil, copper ball, gold salt, ink, dry film, etc. In these raw materials, copper clad plate accounts for about 37% of the cost. The copper-clad plate used for 5G needs to meet the requirements of high frequency and high speed transmission.

Have high frequency production of high-speed copper clad manufacturers less, and copper clad industry concentration is higher, for the downstream PCB manufacturers bargaining power is stronger, 5G for the special requirements of copper clad, cause the rise of overall costs, copper clad prices, the cost rise further to the PCB manufacturers, and backward capacity, backward technology, with low price strategy to seek market of small and medium-sized PCB manufacturers for customer bargaining power is weak, and lack of money hard to avoid bankruptcy.

With the development of The Times, the PCB industry will also be reshuffled.