-

Difficulties and precautions in processing thick copper circuit boards

May 24,2023

Heavy Copper PCB Manufacturing Up to 20 oz PCB Manufacturing, rich experience to print solder mask, High quality guarantee for extreme copper PCB. Send Your Inquiry to Sales@ucreatepcb.com, we will quote you in 2 hours! Thick copper PCB is divided into single-sided thick copper circuit board, double-sided thick copper circuit board and multi-layer thick copper circuit board. Because of the thicker...

Read More

-

The Key Factors Influencing the Thermal Conductivity of Aluminum-Based PCB

May 24,2023

We Mainly Bulid Volume Production & High Difficult Printed Circuit Boards for 18+ years! Send Your Inquiry to Sales@ucreatepcb.com, we will quote you in 2 hours! Introduction Aluminum-based circuit boards have gained significant popularity in the electronics industry due to their excellent thermal conductivity properties. As electronic devices continue to become more compact and powerful, effi...

Read More

-

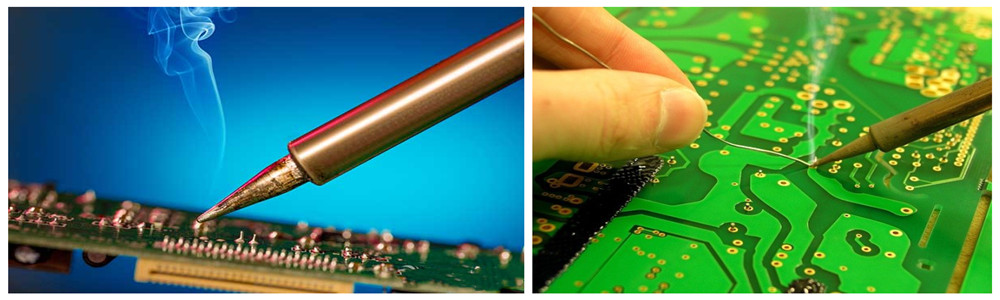

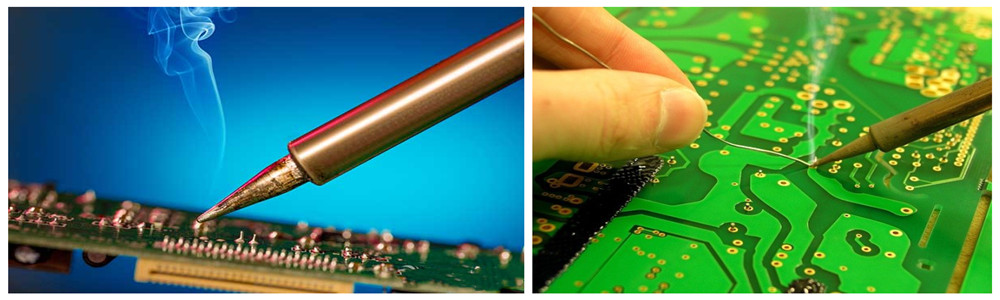

The Precautions of Circuit Board Soldering

May 26,2023

The Precautions of Circuit Board Soldering

May 26,2023

In PCB assembly manufacturers, circuit board soldering usually includes reflow soldering, wave soldering and electric soldering iron soldering. Reflow soldering and wave soldering are SMT patches, which are less affected by human factors. Electric soldering iron soldering is manual soldering, which is affected by human factors. relatively large impact. Ucreatepcb provides intelligent manufacturing...

Read More

-

Why The Car Circuit Board Burns Out?

May 26,2023

We Mainly Bulid Volume Production & High Difficult Printed Circuit Boards for 19+ years! Send Your Inquiry to Sales@ucreatepcb.com, we will quote you in 2 hours! Common reasons for car circuit board burnout are as follows: 1. Power supply problem. The work of the automotive circuit board requires a suitable voltage range. When the voltage exceeds or falls below the voltage, the circuit is...

Read More

-

The Common Failures of PCBA Board

Jun 17,2023

In the production and processing of SMT , various faults of circuit boards are often encountered, so what are the common ones? What is SMT Assembly? How to Choose A Good SMT Factory? The Precautions of Circuit Board Soldering 1. Weld failure Soldering problems account for the majority of PCB defects in SMT factories . Working with tiny components on a pcb board makes the soldering technique more c...

Read More

-

FPC Impedance Boards

Jun 28,2023

FPC Impedance Boards

Jun 28,2023

The FPC impedance board is a very practical circuit board production technique with numerous advantages and functions. Here we will look at the uses of FPC resist boards and the role they play in the production of flexible circuit boards. What is the difference between FPC flexible boards and PCB rigid boards? FPC Cable and Its Use How FPC Flexible Circuit Boards Are Processed? Firstly, let's look...

Read More

-

What Are The Methods of PCB Drawing Process?

Jun 29,2023

What Are The Methods of PCB Drawing Process?

Jun 29,2023

The entire PCB drawing process is divided into the following steps: 1. Determine the PCB design plan before PCB drawing, you need to specify the specific needs of the circuit board to be drawn. Including the size of the circuit board, the number of layers of the board, the material of the board and the copper laying of the PCB board and other aspects. 2. Draw the circuit schematic drawing PCB proc...

Read More

-

Multilayer PCB Board Fabrication

Jun 29,2023

Multilayer PCB Board Fabrication

Jun 29,2023

With the continuous development of electronic technology, the use of multilayer PCB boards is becoming more and more extensive. Unlike single-layer or double-layer pcb boards, multi-layer boards can achieve higher integration while ensuring circuit functions. So in the process of making multi-layer PCB, what key skills need special attention? Related Posts What's Multi-layer PCBs and advantages? T...

Read More

The Precautions of Circuit Board Soldering

May 26,2023

The Precautions of Circuit Board Soldering

May 26,2023

FPC Impedance Boards

Jun 28,2023

FPC Impedance Boards

Jun 28,2023

What Are The Methods of PCB Drawing Process?

Jun 29,2023

What Are The Methods of PCB Drawing Process?

Jun 29,2023

Multilayer PCB Board Fabrication

Jun 29,2023

Multilayer PCB Board Fabrication

Jun 29,2023