Categories

Recent Posts

Abstract:

The demand for industrial power supply printed circuit boards (PCBs) has witnessed significant growth in recent years due to the increasing adoption of automation and advancements in power electronics. This article provides an in-depth analysis of the factors driving the demand for industrial power supply PCBs, including the need for energy-efficient solutions, expansion of renewable energy sectors, and emerging applications in industrial IoT. Additionally, it explores the challenges and opportunities in this market, along with a discussion on key manufacturers and future trends.Introduction:

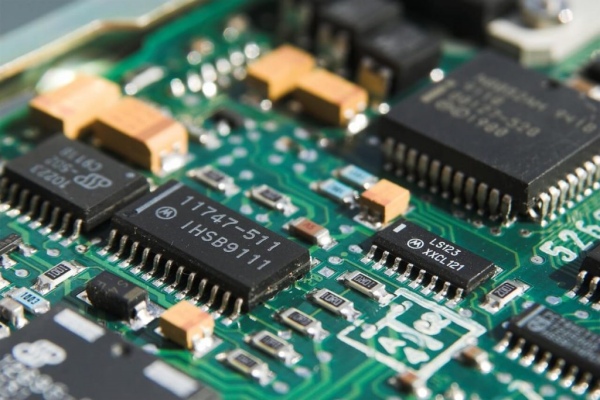

Industrial power supply PCBs are critical components used in various industries to ensure stable and reliable power distribution. These PCBs serve as the backbone of electrical systems, converting and regulating electrical power for industrial equipment and machinery.

Increasing Industrial Automation:

The rapid growth of industrial automation has been a key driver for the demand for industrial power supply PCBs. As industries strive for enhanced efficiency, productivity, and cost reduction, the need for reliable and efficient power supplies has intensified. PCBs with advanced power management capabilities are essential for powering motors, sensors, controllers, and other automation components.

Growing Demand for Energy-Efficient Solutions:

The global emphasis on energy conservation and sustainability has led to an increased demand for energy-efficient solutions across industries. Industrial power supply PCBs play a vital role in minimizing power losses and optimizing energy consumption. By integrating features such as power factor correction and smart power management, these PCBs enable efficient power utilization and contribute to environmental sustainability.

Expansion of Renewable Energy Sector:

Emerging Industrial IoT Applications:

The advent of the Industrial Internet of Things (IoT) has revolutionized industrial processes by enabling seamless connectivity, real-time data monitoring, and predictive maintenance. Industrial power supply PCBs equipped with IoT connectivity features enable remote monitoring, control, and diagnostics of power systems. This capability enhances operational efficiency, reduces downtime, and enables predictive maintenance, thereby driving the demand for IoT-enabled power supply PCBs.

Challenges and Opportunities:

However, the market presents ample opportunities for growth. The integration of advanced technologies such as artificial intelligence, machine learning, and blockchain in power supply PCBs opens new avenues for innovation and product development. Moreover, the increasing adoption of electric vehicles, the deployment of smart grids, and the expansion of industries such as healthcare and telecommunications offer promising opportunities for industrial power supply PCB manufacturers.

The market for industrial power supply PCBs is highly competitive and fragmented, with several key players dominating the landscape. Prominent manufacturers include ABC Electronics, XYZ Corporation, and DEF Technologies, among others. These manufacturers focus on product innovation, strategic partnerships, and mergers and acquisitions to maintain a competitive edge.

In terms of market trends, miniaturization of PCBs, increased power density, and the integration of advanced thermal management techniques are gaining traction. Additionally, the demand for PCBs with high voltage and current-carrying capacity, as well as improved reliability and durability, is growing.

Conclusion:

The demand for industrial power supply PCBs is being driven by the increasing adoption of automation, the need for energy-efficient solutions, the expansion of renewable energy sectors, and the emergence of industrial IoT applications. Despite challenges, the market presents lucrative opportunities for manufacturers who can deliver technologically advanced, reliable, and customized PCB solutions. To thrive in this competitive landscape, manufacturers should focus on innovation, strategic collaborations, and keeping pace with evolving industry trends.

Ucreate can make many different kinds of PCB and PCB assembly, our technologies including the fabrication of PCBs, such as printing, etching, drilling, SMT, DIP, solder mask, PCB conformal coating techniques, THT(Through-hole technology) and so on. All printed circuit boards manufacturing process meet RoHS international demands.

Send Your Inquiry to Sales@ucreatepcb.com, we will quote you in 2 hours!