Categories

Recent Posts

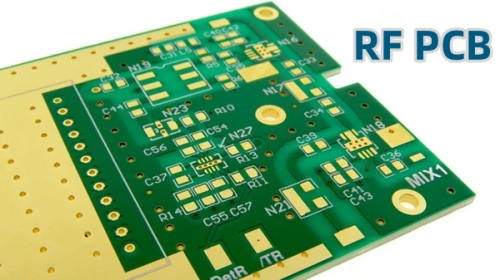

RF PCB stands for Radio Frequency Printed Circuit Board. It refers to a type of printed circuit board specifically designed for high-frequency electronic applications, such as wireless communication, radar systems, microwave devices, and other RF (Radio Frequency) applications. RF PCBs are engineered to have precise impedance control, minimal signal loss, and reduced electromagnetic interference at high frequencies. These boards often use specialized materials and design techniques to ensure the reliable transmission and reception of RF signals.

FR4 is a commonly used material for RF (Radio Frequency) PCBs, and its typical application frequency ranges from a few megahertz (MHz) to several gigahertz (GHz). The exact frequency range depends on various factors such as the PCB design, component selection, and manufacturing quality. However, FR4 is generally suitable for applications in the range of a few MHz up to a few GHz. For higher frequencies, specialized materials like Rogers or PTFE-based substrates are often preferred due to their improved electrical properties and lower signal loss.

Radio frequency PCB material selection

Radio frequency (RF) circuit design, PCB material selection has a direct impact on circuit performance. FR4 is a commonly used substrate, mainly used in low-frequency, circuit complexity of small PCB boards, the use of the frequency is generally within 1-2GHz, the signal integrity, impedance matching is not too demanding. For high-frequency applications, the electrical and thermal properties of FR4 limit its application.

The characteristics of FR4 materials

FR4 (Glass-Reinforced Epoxy) glass fibre reinforced epoxy resin plate, the advantages of water absorption is small, stable electrical properties, good dimensional stability, good processing performance, while the price is relatively inexpensive, the shortcomings are the dielectric constant is high, the dielectric loss is large, the impact on the RF signal transmission is greater, adapt to the lower frequency.

Compared with other materials

RF PCB commonly used materials such as TEFLON, Rogers, FR4, etc. TEFLON is an organic polymer, characterized by low loss, high dielectric constant, high frequency band applications, while Rogers is an inorganic ceramic, with a low dielectric constant, high-frequency band applications, but the price is high, dimensional stability and other aspects of the problem. FR4 material has its unique advantages, mainly low cost, processing easy and better dimensional stability.

RF pcb board fr4 has good performance in low-frequency applications, the use of frequency is generally in 1-2GHz, is a common basic material in the electronics industry. However, its relatively large dielectric constant and dielectric loss result in poor performance in high frequency applications, requiring the selection of other PCB materials more suitable for high frequency applications. In RF PCB design, choosing the right material is an important factor in ensuring product performance.

Related Posts:

1. 7 Factors Affecting RF PCB Design

2. The quality control of PCBA processing

3. How to Choose PCB Suppliers?

Welcome to consult our sales engineer with BOM list and Gerber file