What is the difference between FPC flexible boards and PCB rigid boards?

2023/04/10

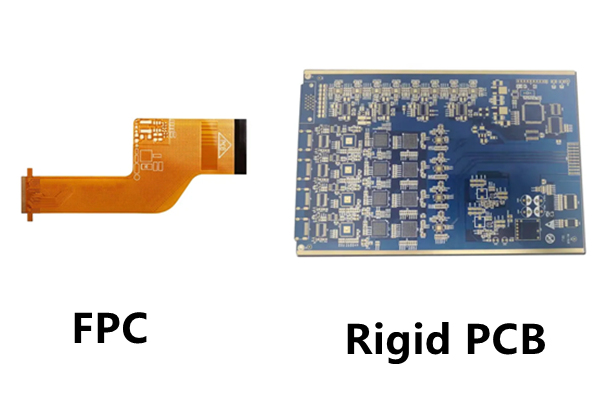

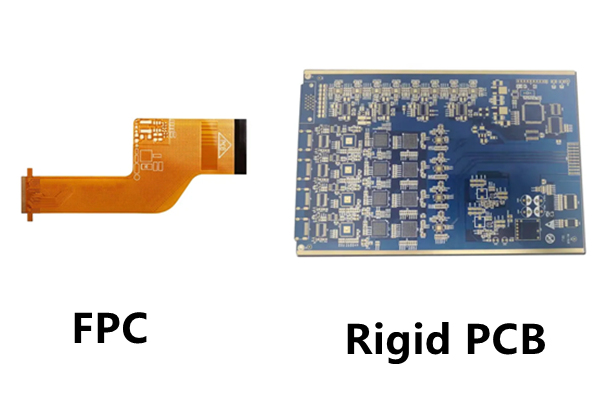

Flexible printed circuit (FPC) boards and rigid printed circuit boards (PCBs) are two types of circuit boards used in electronic devices. The main difference between FPC and PCB is their flexibility and rigidity.

FPC boards are made of a flexible material such as polyimide or polyester film, which allows the board to be bent, twisted, or folded to fit into tight spaces or conform to the shape of the device. FPCs are typically thinner and lighter than rigid PCBs, which makes them ideal for applications where space is limited or weight is a concern.

On the other hand, PCBs are made of a rigid substrate material such as fiberglass or epoxy resin. These boards are inflexible and cannot be bent or twisted. PCBs are widely used in electronic devices that require high levels of precision, durability, and stability.

Another key difference between FPC and PCB is their manufacturing process. FPCs are typically made using a roll-to-roll process, which involves printing the circuit pattern onto a flexible substrate material and then etching away the unwanted copper. PCBs, on the other hand, are made using a subtractive process, which involves drilling holes and cutting away the unwanted copper from a rigid substrate material.

In summary, the main differences between FPC flexible boards and PCB rigid boards are their flexibility and rigidity, thickness, weight, and manufacturing process. FPCs are ideal for applications where space and weight are a concern and flexibility is required, while PCBs are ideal for applications that require high levels of precision, durability, and stability.

Send PCB Files to Sales@ucreatepcb.com, We Will Quote You Very Soon!

Request PCB Manufacturing Quote