Categories

Recent Posts

Ucreate UL parameter update

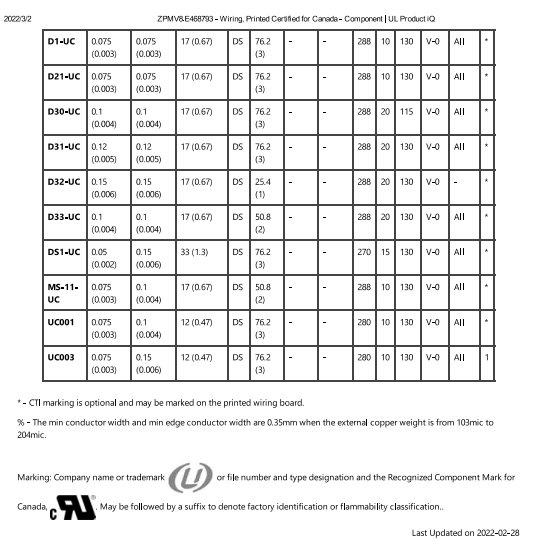

Our company UCREATE Electronics Group have update the UL parameter, more raw materials and Solder Resists were certified, such ad S1000-2M, IT 180A, KB-6165F, S1600L,and TAIYO etc, the min trace space/ width is 0.075mm, and we We also applied for trademark certification.

The trademark as below.

And the details as below.

Those seeking quality printed circuit boards may look for boards that are UL approved. UL is short for Underwriters Laboratories, a global independent safety science company with over 100 years of expertise innovating safety solutions. UL is an accepted leader worldwide in testing, certification and standards development, with a goal to use safety science and safety engineering to promote safe living and working environments. Having a UL logo on your board certifies that your PCB has been verified to have been designed according to UL standards for quality and safety.

UL recognition addresses component safety concerns such as flammability and electric insulation. Those who buy UL-recognized PCB products can be confident that these boards comply with accepted component safety requirements. It will get lead time and quote for Your Board.

What is UL certification?

The main standards of PCBs are UL 796, the specific PCB standard, and the UL 94 for flammability of plastics materials. These specify many performance tests to measure the long-term reliability and fire safety of the PCB. If a board is released in accordance with these standards, the board will be marked with the Underwriters Laboratories (UL) logo.

The parameters used for PCB certification will be determined by the application of the circuit board in its final product. Some industries have some specific standards and vary parameters in UL certifications, such as specific flame rating, direct support requirements (DSR), maximum operating temperature (MOT), the relative thermal index (RTI), and minimum comparative tracking index (CTI) rating. The requirements of these parameters may be different for the PCBs based on different applications of the end-products.

There are two levels of PCB recognition that manufacturers can apply for: full recognition and flammability-only recognition. The type of PCB identification required depends on the application of PCBs in the end-products. Materials, construction, parameters, and manufacturing process are the main elements controlled for a recognized PCB. Therefore, when customers indicate that the PCBs need to meet UL, customers need to specify the UL parameters required for the PCB applications of the end products. Or tell PCB manufacturers whose field is the PCBs applied in.

Why UL certification is important?

UL is the only organization that publishes PCB safety standards. UL certification can demonstrate the PCB products have been passed the product safety benchmark. And the UL recognized PCBs could be used globally.

It is well known that UL recognized PCB components and materials had passed the industry' s most stringent safety tests and follow-up program. With UL certification on the PCBs, PCB manufacturers can assure customers that the boards they get a match or exceed industry standards for preventing the electric shock or fire. It has been certified for safe use and follows specific standards and guidelines during development and construction.

If PCB manufacturers produce PCBs for industries that do not have UL certifications, manufacturers may not need to certify the boards. But, many end products now also require PCBs to meet UL standards, such as audio and video equipment, medical equipment, and industrial control equipment, etc. In any case, if the boards are officially certified according to industry safety standards, PCB manufacturers will be more attractive than the competitors.

Types of UL certification

UL certifies PCBs under a PCB Recognition Program that comes in two flavors – Full Recognition and Flame-Only Recognition.

Flame Ratings

Flame ratings are typically specified by end product requirements and evaluate a sample burn time when a PCB is subjected to a horizontal and vertical flame. These flames are broken down into classes which includes V-0, V-1, V2, VTM-0, VTM-1, and VTM-2.

Solder Limits

Solder limits test the kind of soldering processes that a PCB will be subjected to during the component assembly process. These tests simulate a thermal shock and maximum temperature to gauge how your PCB performs.

Maximum Operating Temperature

Maximum Operating Temperature (MOT) defines a PCBs maximum continuous use at a specific temperature. This test simulates the exposure of a PCB to normal operating condition temperatures during a 10-56 day period, with temperatures based on your manufacturer’s guidelines.

Direct Support Request

Direct Support Request (DSR) measures the performance of a PCB laminate when in contact with 120V or less. This test is only performed on laminates rather than the whole PCB, and each laminate receives a DSR compliant rating. During this testing, a laminate will undergo several performance tests, including:

·Dielectric strength

·High current arc ignition

·Hot wire ignition

·Volume resistivity

·Heat deflection