Categories

Recent Posts

The whole process of PCBA circuit board machining includes PCB processing, component procurement and inspection, SMT chip and DIP plug-in after welding, etc. The whole PCBA circuit board processing process involves a wide range, including many quality control details. If there is no very strict quality control standards, it will lead to PCBA circuit board quality abnormal, the inspection standards are not strict or there is no standard to follow, it is likely to be a small link error will lead to the whole batch of PCBA circuit board scrap or need to be repaired, resulting in serious quality accidents. So, how to do a good job of PCBA circuit board and xia quality control work?

1.PCB circuit board machining

After receiving the order of the PCBA circuit board, analyze the Gerber file, pay attention to the relationship between the hole spacing of the PCB and the bearing capacity of the board, do not cause bending or fracture, whether the wiring considers the interference of high frequency signal, Impedance and other key factors.

2. Components procurement and inspection

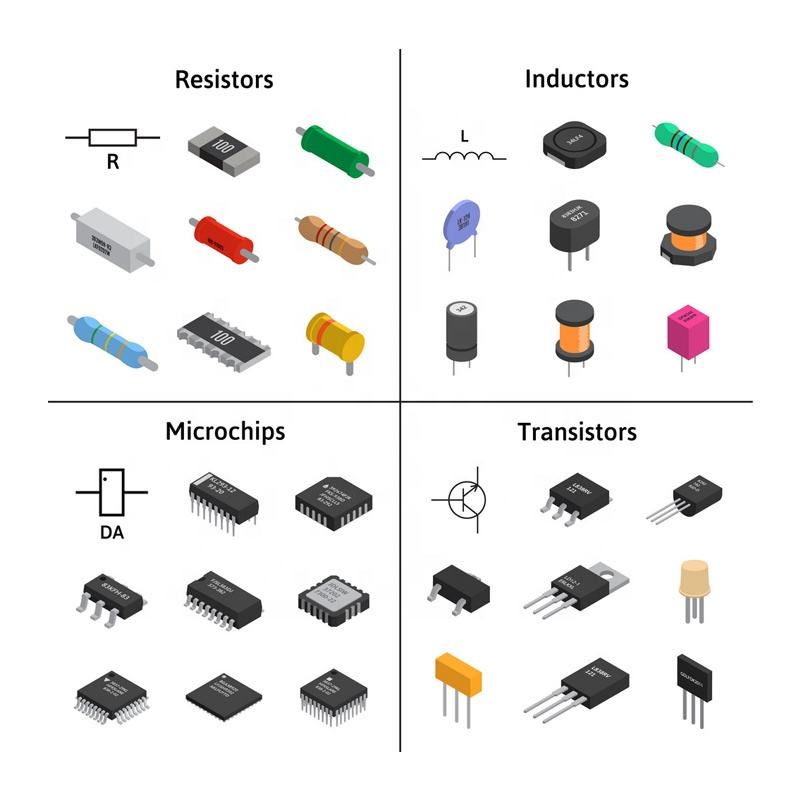

In order to ensure the stability and quality of components, it is necessary to strictly control the purchase channels of suppliers and the qualification of suppliers. Generally designated from the large traders and the original manufacturers to take goods This can avoid the use of used materials and counterfeit materials. In addition, it is necessary to set up a special PCBA incoming material inspection post to strictly inspect the following items to ensure that the parts are not faulty. PCB: check the temperature test of the reflux welding furnace, whether the hole is blocked or ink leakage, and the plate surface is apricot bending, etc. IC: Check screen printing with BOM and keep at constant temperature and humidity. Other commonly used materials: check screen printing, appearance, power-on value, etc.

3. SMT chip machining

Tin paste printing and temperature control of reflux welding furnace are the key points, and it is very important to use laser steel mesh with good quality and meet the process requirements. According to the requirements of PCB, some of the steel mesh needs to be enlarged or reduced, or the U-shaped hole is used to make the steel mesh according to the process requirements. The furnace temperature and speed control of reflow welding are very critical for the overflow and welding reliability of tin education, which can be controlled according to the normal SOP operation guidelines. In addition, the AOl testing needs to be strictly implemented to minimize the adverse factors caused by human factors.

4. DIP plug-in machining

In the process of plug-in processing, the mold design details of wave crest welding is the key. How to use the mold carrier to greatly improve the yield rate, this is the PE engineers must constantly practice and summarize the process experience.

If there are no problems with the PCB board and no problems with the components. We can pay attention to the control of details in the whole processing process, and the whole PCBA circuit board processing quality can be guaranteed.

In 2008,UCREATE ELECTRONIC GROUP Set up the SMT & Assembly factory in Shenzhen,No. of Employee: 1,200 (as of Jun .2015) Covered an area of 4,100 square meters. The plant’s monthly productive capability reached 30,000 square meters. With clients all over the world. Welcome to enquire for a long-term partnership!!