Categories

Recent Posts

The last article we learned about the PCB several ways to put together the board, then Panelization should take into account the connection between the board, there are generally three kinds: V-CUT, stamp holes and Dummy strips. V-cut for the rule of the board is used more, as long as the two boards put together, leaving a little space between them (the gap between the V-cut) can be. Stamp holes are more commonly used in shaped boards, where multiple holes are punched where the boards meet. Dummy strips are where very narrow plates are used to join, and are used more in boards that have a half-hole process.

1. V - cut

V-CUT is a V-shaped cut along a preset line at the adjacent PCB board splice by means of a specific cutting device, forming a cut slot of moderate depth. The connection of the boards at this place is thinner and easier to break. Just merge the edges of the two boards together during Panelization.

The precision of the V-cut is one of its major advantages. Advanced V-cut equipment can precisely control the cutting depth and angle, and the error range can be controlled within a very small range. This effectively protects the precise lines on the PCB board and reduces the risk of line damage caused by the cutting operation. At the same time, the edge of the V-cut is relatively smooth, reducing the generation of burrs, which in turn reduces the probability of short circuits, circuit failures and other problems caused by burrs.

In the field of electronic products, V-cut is the preferred connection method for those products that require extremely high dimensional accuracy of circuit boards, such as high-end smart phones and precision medical electronic devices. It ensures that the dimensions of each small board are highly consistent during Panelization and depaneling to meet the compact design and high performance requirements of electronic devices.

Since the V-cut can only go in a straight line, it is only suitable for regular PCB Panelization. For irregular PCBs, such as round ones, it is necessary to use to stamp holes for Panelization connection.

2. Stamp hole

Stamp holes are another type of connection for Panelization and are generally used more often in shaped panels. The edges of two boards are joined by a small piece of sheet material which is connected to the two boards by a number of small round holes. The walls of these round holes are usually metallised to ensure a good electrical and mechanical connection.

he high connection strength of the stamp holes effectively prevents the relative displacement or shaking of the small plates during production and handling and ensures the stability of the Panelization. When splitting the board, use special tools to cut or break along the edge of the stamp hole, the operation is relatively convenient, and is not easy to damage the surrounding lines and components.

Stamp holes are widely used in the assembly of small, multi-functional electronic products, such as smart bracelets, small headphones and so on. These products PCB board area is small, stamp holes can not only meet the mechanical connection requirements, but also save Panelization space, improve space utilization.

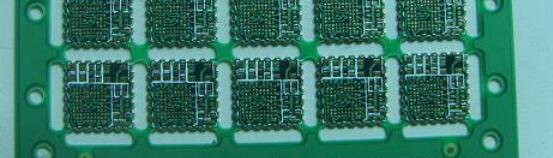

A complete stamp hole is shown in the figure below:

3. Dummy strip

Dummy strips are made of long, thin strips of material with a hollow centre. During Panelization, the Dummy strips are inserted or, in some cases, taped to neighbouring PCBs.

Dummy strips are flexible and relatively easy to install and remove. At the connection point, due to its hollow structure, the stress can be evenly distributed, reducing the phenomenon of stress concentration and reducing the risk of damage to the corner areas of the PCB board.

Dummy strips are suitable for electronic products with requirements for cost control and lightweighting, such as low-end consumer electronics, industrial control equipment with simple functions. It can meet the basic Panelization and sub-panel requirements while reducing production costs and reducing the overall weight of the PCB.

In the actual PCB Panelization production process, need to take into account the characteristics of electronic products, performance requirements, cost budget and other factors, a reasonable choice of V cut, stamp holes, Dummy strips of the three connection methods, in order to improve product quality and production efficiency. If you have any needs about PCB manufacturing, please feel free to contact us.

Welcome to consult our sales engineer with BOM list and Gerber file