Categories

Recent Posts

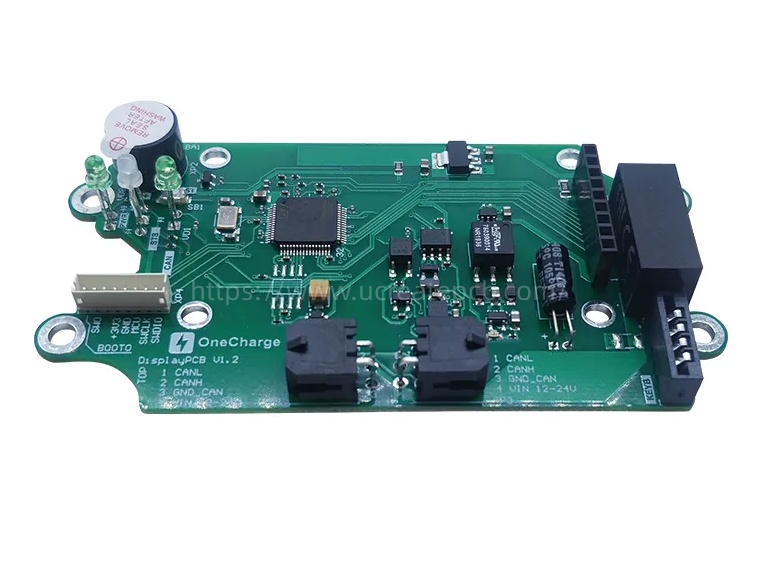

With the continuous progress and development of science and technology, it is widely used in the field of energy storage. Energy storage PCBAs play a vital role in power systems, electric vehicles, solar cells, and various other energy devices. This article will delve into the energy storageThe process characteristics of pcb a patch and the details that need to be paid attention to during the production process.

1. Environmental requirements:

During the use of energy storage PCBA, it may face various environmental conditions, such as high temperature, low temperature, humidity, etc., and has high requirements for the environment. Therefore, in the production process, measures must be taken to ensure that the PCBA can work normally in various extreme environments. Among them, ambient temperature test and humidity test are indispensable links.

2. Material selection:

There are many kinds of materials involved in energy storage PCBA, such as substrate, solder, components and so on. When choosing a material, its stability, reliability and durability must be considered. Especially in harsh environments such as high pressure, high temperature, and high humidity, materials must function properly without causing problems such as damage or short circuits.

3. Welding process:

Soldering is a critical step in the production process of energy storage PCBA. Using a suitable welding process can ensure the quality and reliability of solder joints. For energy storage PCBAs, commonly used soldering techniques include surface mount technology (SMT) and wave soldering techniques. These technologies ensure that the connection between the component and the substrate is strong and reliable, and can operate normally under various operating conditions.

4. Details processing:

During the manufacturing process, special attention to detail is required. For example, when welding components, the welding time and temperature must be strictly controlled to prevent quality problems caused by overheating or poor welding. In addition, during the component installation process, it is also necessary to pay attention to the correct direction, position and spacing of the components, etc. Only when these details are guaranteed, can the energy storage PCBA have good performance and reliability.

5. Quality control:

To ensure the quality of energy storage PCBA, quality control is indispensable. During the production process, strict quality inspection is required, including appearance inspection, function test, reliability test, etc. Only by passing these tests can the reliability and stability of PCBA in practical applications be guaranteed.

In summary, energy storage PCBA, as a key electronic component, has important applications in the field of energy storage. During the manufacturing process, aspects such as environmental requirements, material selection, welding process, detailing and quality control must be considered. Only through reasonable process characteristics and strict quality control can the performance and reliability of energy storage PCBA circuit boards be guaranteed to meet the needs of use in various extreme environments.

Send Your Inquiry to Sales@ucreatepcb.com, we will quote you in 2 hours!